Pd-based silica (Si/Al > 50) small pore zeolite catalysts with increased durability and improved low temperature CH4 oxidation performance (> 90% CH4 conversion at temperatures < 400ºC).

Natural gas has garnered attention as a cleaner alternative fuel for vehicles compared to gasoline or diesel. Natural gas vehicle (NGV) exhaust contains methane (CH

4) which is 25 times more harmful than carbon dioxide (CO

2) in global warming potential. The conventional solution for CH

4 remediation is its catalytic oxidation using Pd/Al

2O

3 catalysts. However, Pd/Al

2O

3 catalysts suffer from low conversions and deactivation through Pd sintering in typical exhausts of natural gas vehicles containing high amounts of water vapor (5-10%) at low temperatures (< 400ºC).

A promising support alternative for Pd/Al

2O

3 catalysts are zeolites that can act as molecular sieves through size limiting pores to restrict Pd sintering. Moreover, the hydrophobicity of zeolites can be increased by increasing the Si content to prevent water inhibition. University at Buffalo and Syracuse University researchers have developed small-pore H-CHA (Si/Al

> 137) and H-LTA (Si/Al

> 39) zeolites loaded with 1 wt.% Pd to achieve low temperature CH

4 oxidation performance.

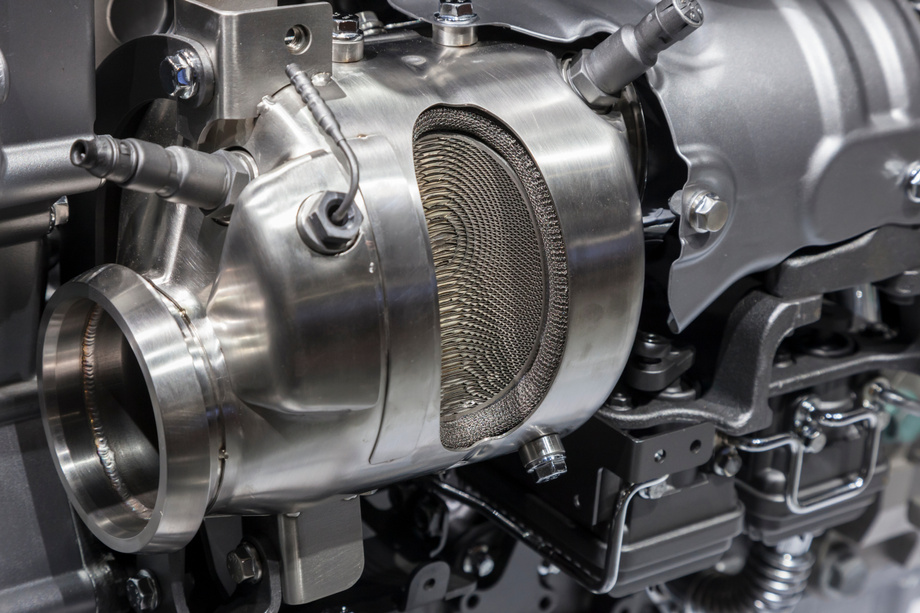

Source: philipus, https://stock.adobe.com/uk/71061866, stock.adobe.com

Source: philipus, https://stock.adobe.com/uk/71061866, stock.adobe.com

- >90% CH4 conversion below 400ºC in simulated natural gas exhaust feed.

- 100% CH4 conversion at 450ºC for more than 10 hours compared to 70% conversion over conventional Pd/Al2O3.

- Catalytic converters for methane oxidation natural gas vehicles.

- Carbon monoxide (CO), hydrocarbon (HC) oxidation, and nitrogen oxide (NO) reduction (three-way catalysts) for diesel and gasoline vehicles.

- Catalytic converter for stationary natural gas engines or diesel engines.

- Catalytic converter for marine vessels.

- Steam or dry reforming of CH4 to syngas.

- Available for licensing and joint development.