Ceramic Membranes for Organic Solvent Nanofiltration

Highly stable nanoporous membranes that enable ultrafast and precise solvent separation.

Given the volume of solvents, catalysts and products used and produced in the chemical, energy, and pharmaceutical industries, there is a strong need for efficient and cost-effective means for their separation. At present, industrial separation can contribute a significant percentage to a product's final cost. While membrane technologies have been explored to address this need, the environments in which they are expected to work, ones which may involve harsh organic solvents as well as elevated temperatures and pressures, present challenges that often preclude their effective use. In many cases, competing membranes either possess low permeance and/or low selectivity.

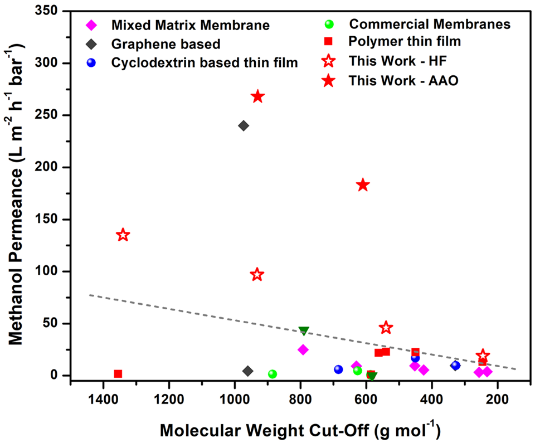

The University at Buffalo invention provides a facile method for fabricating nanoporous membranes that are not only stable across a variety of organic solvents as well as at elevated temperatures and pressures but also demonstrate high permeance and selectivity. Compared to certain state-of-the-art membranes, the membranes resulting from this method provide 2.5 to 10 times higher permeance while maintaining equivalent or higher selectivity, the combination of which may enable use of smaller membranes for existing separation processes. The molecular weight cutoff (MWCO) of these membranes can be precisely controlled in the range of 200-1,000 Da, with a step change of approximately 100 Da.

- Simple and tunable fabrication

- High stability

- High permeance

- High selectivity

- Nanofiltration

- Semiconductor

US National patent 18/865,742 filed Nov. 14, 2024

Laboratory demonstration

Available for licensing or collaboration

DOI: 10.1126/science.adh2404

Patent Information:

| App Type |

Country |

Serial No. |

Patent No. |

Patent Status |

File Date |

Issued Date |

Expire Date |

|