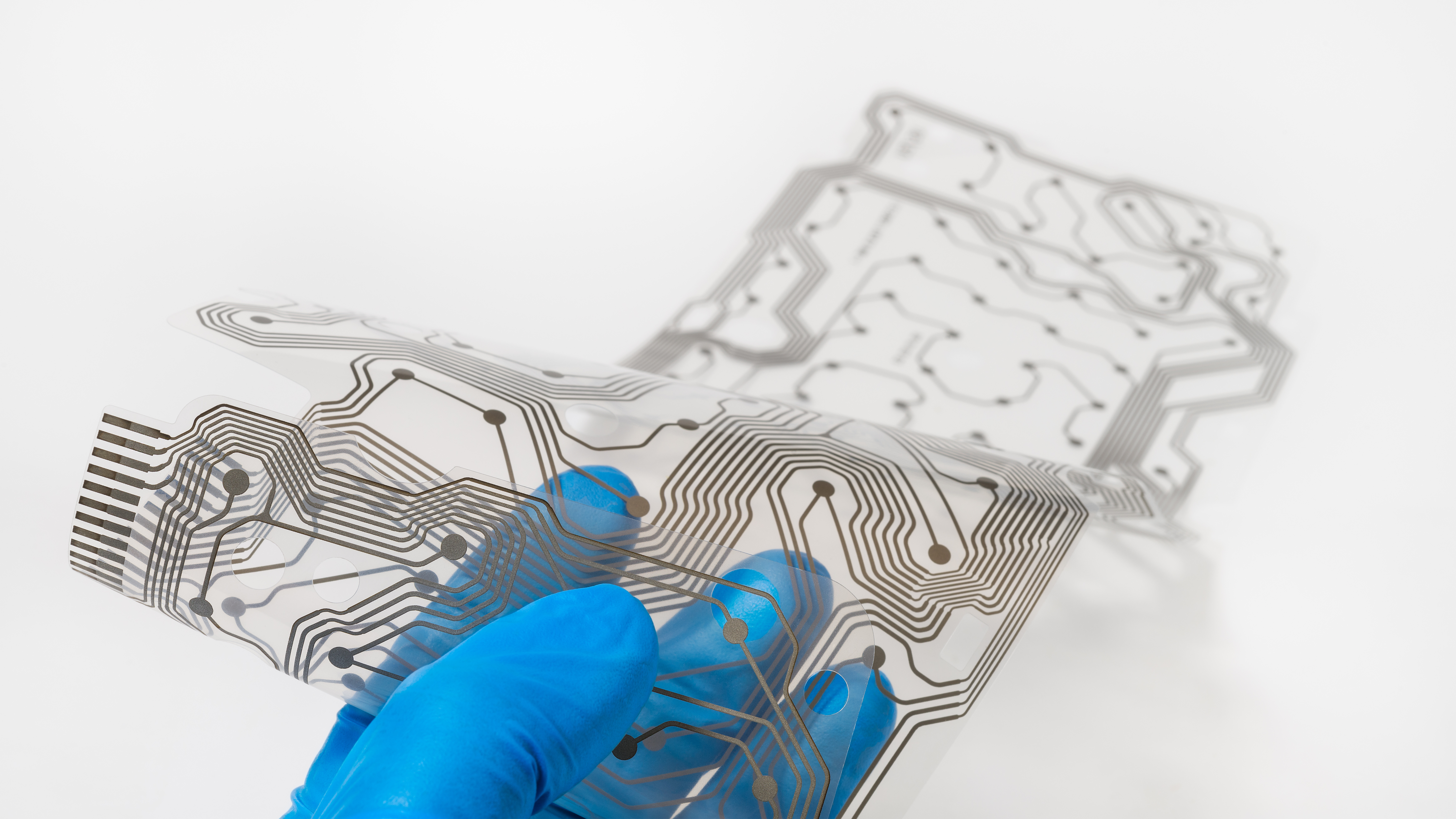

This technology is a novel method for fabricating metal substrates for flexible electronics, producing improved components at lower cost.

Flexible electronics comprise an emerging technology that has gained considerable attention in recent years due to its potential applications in wearable devices, biomedical sensors, and other flexible electronic devices. One of the key challenges in the development of flexible electronics is the selection of suitable substrates that can withstand the mechanical stress caused by bending and stretching. Metal substrates have emerged as a promising alternative to conventional polymer substrates due to their high thermal conductivity, good electrical conductivity, and excellent mechanical properties. Various metals such as copper, aluminum, stainless steel, molybdenum, and titanium have been investigated for use as flexible electronic substrates.

To produce metal wafers comparable to the quality of silicon, this technology is a method to hot press metal wafers sandwiched between silicon wafers. This not only improves flatness, but also decreases the surface roughness of the wafers. To do this, the technology uses silicon wafers, which have ultra smooth surfaces. Further, the eutectic point of silicon with most refractory metals (Mo, W, Ta) lies at high temperatures (~1000 C). The flattening time, temperature, and pressure are optimized to achieve wafer quality to silicon standards. This unique approach improves the wafer quality by eliminating the number of process steps and thus the cost of metal wafer production for flexible electronic applications.

• Improves wafer quality.

• Eliminates the number of process steps.

• Reduces cost of metal wafer production for flexible electronic applications.

The primary application for this technology is the production of flexible electronics. Flexible electronics are used in cell phones, wearable devices, displays, and many other applications.

Patent application filed – 18/654,117 - updated 04/22/2025

TRL 3 - Experimental proof of concept

This technology is available for licensing.

This technology would be of interest to anyone involved in the manufacture of flexible electronic components and devices, including:

• Electronic component manufacturers.

• Electronic devices manufacturers.

• Research institutions.