Nanomaterials Construction of Thermal Interface Materials

A hybrid thermal interface material that minimizes the thermal resistance between two solid surfaces, that can be used for applications requiring high thermal dissipation

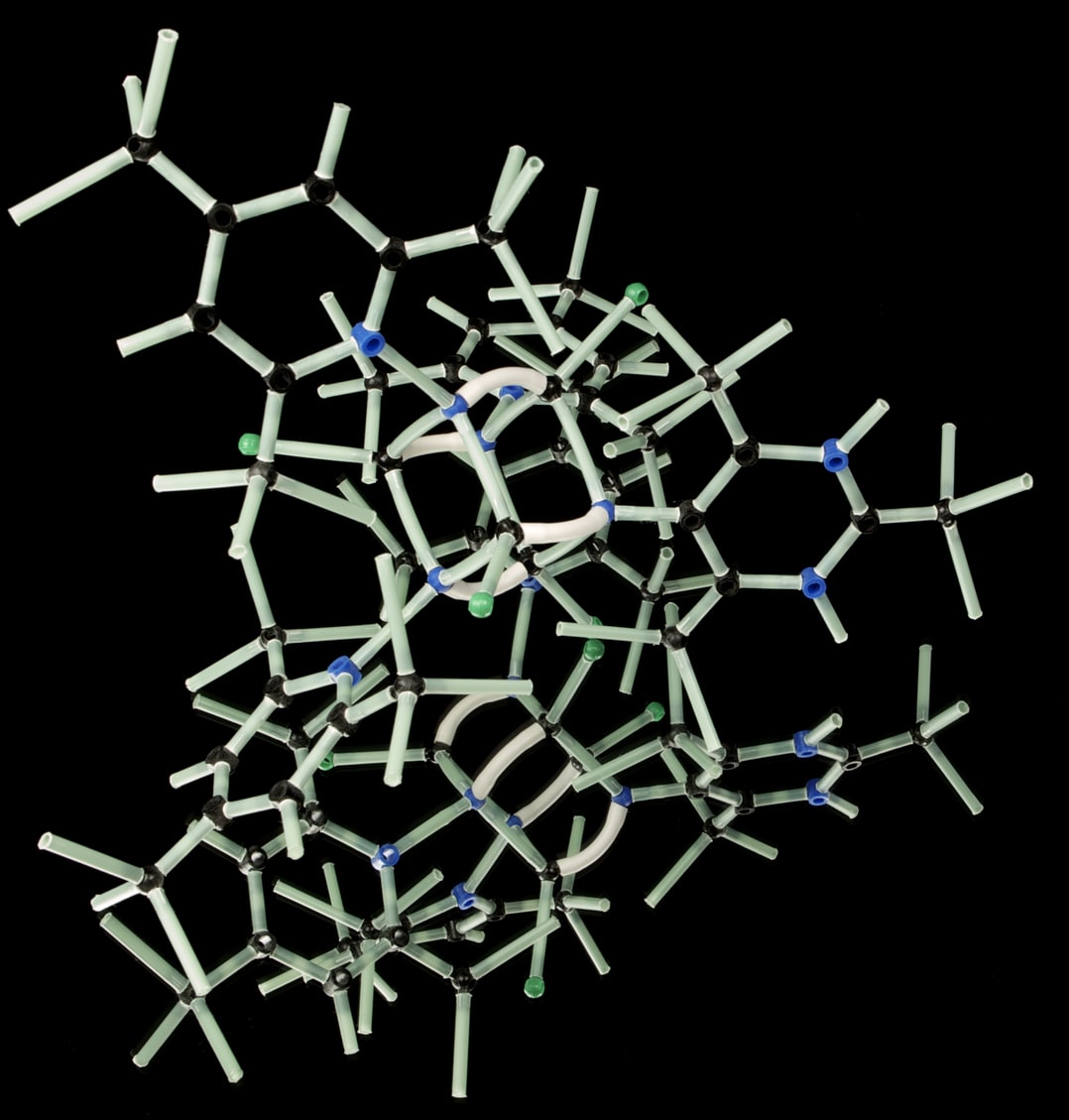

This invention covers the system-level design, use and placement of a hybrid Thermal Interface Material (TIM) system comprised of a matrix of aligned Carbon nanotubes (CNT) with deformable surfaces that form intimate contacts with deformable, metallic capping layers that are in contact with the chip and the heat sink on the top and the bottom. The thickness and density of the CNT array within the mat (sheet) can be changed to match the heat dissipation needs of hot spots. This TIM solution minimizes the thermal resistance between two solid surfaces, and can be useful for any applications requiring very high thermal dissipation by joining two solid surfaces. The single materials system encompasses the following features: (1) high bulk thermal conductivity close to theoretical limit of a composite containing CNTs, (2) readily deformable surfaces to form intimate contacts with solid surfaces of varying topological and roughness features, (3) variable thickness that can be minimized to a few microns, (4) mechanical robustness that meets the requirement for easy processing and application of TIM, as well as long term stability for thermal cycling, and (5) high chemical stability for environmental and manufacturing friendliness. In contrast to typical TIM materials used in production today such as thermal greases and adhesives and low melt point solders such as Indium alloys with thermal conductivity in the 3 to 80 W/mK range, carbon nanotubes (CNTs) may theoretically conduct (bulk) between 6,000-8,000 W/mk. However, actual performance has been much lower due to low conductance at the interfaces between TIMs and solid surfaces.

https://unsplash.com/photos/_y4LGVTeBwQ

https://unsplash.com/photos/_y4LGVTeBwQ

- Compatible with current industry tooling which will facilitate adoption by manufacturers of system-level packages.

- Volume of CNTs at particular points in the mat can be designed to map to hot spots on chips.

- As a hybrid system, offers practical way (performance – cost) to take advantage of super high, thermally-conductive, vertically aligned CNTs embedded in a metal capped pasted.

- Mechanically strong and chemically stable.

Patent Information:

| App Type |

Country |

Serial No. |

Patent No. |

Patent Status |

File Date |

Issued Date |

Expire Date |

|