A New Process to Prepare Pt Alloy Nanoparticles

A Process to Prepare smaller, mono-disperse Pt alloy nanoparticles by controlling the annealing temperature that increases their durability

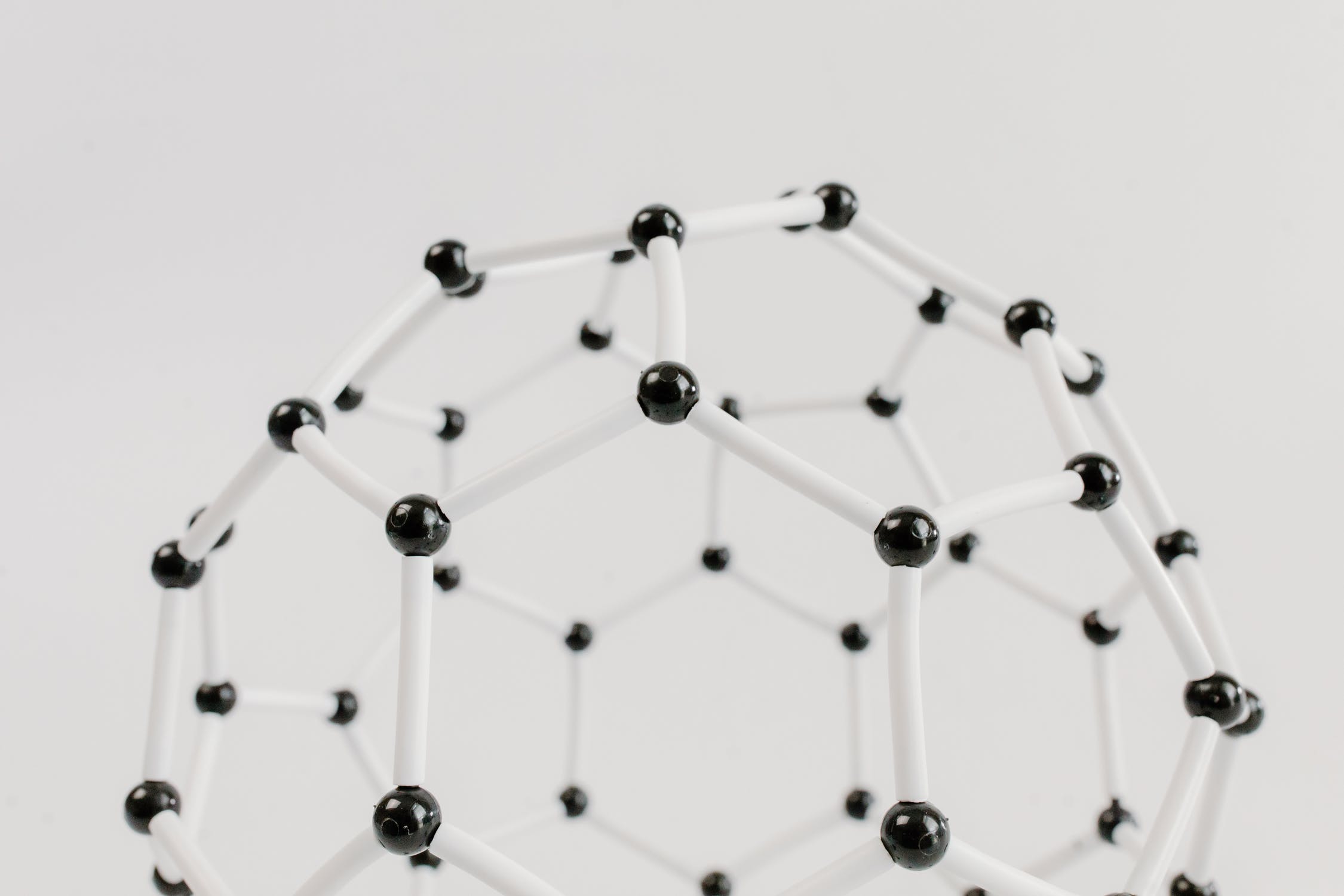

Pt alloy catalysts are potential candidates to replace pure Pt catalysts in fuel cells due to their higher activity. However, the activity and durability of the Pt alloys highly depend on the preparing method.The Pt alloys prepared by conventional impregnation method usually have large particle size, and element distribution in these particles is not uniform.

In this invention, a modified post-treatment of Pt alloy catalysts prepared by the polyol method are proposed. After the nanoparticles are loaded on supports, the capping agents are carefully removed in an inert atmosphere (N2, Ar, etc.) by keeping the temperature at around 270C. After removing the capping agents and pre-annealed at 400C, the supported catalysts are further annealed at elevated temperatures up to 1200C (preferably 700-1000C) to improve the durability and activity.

https://www.pexels.com/photo/internet-connection-school-technology-7723393/

https://www.pexels.com/photo/internet-connection-school-technology-7723393/

- Avoid particle aggregation by minimizing the carbon and metal nanoparticles burning during the capping agents removal process.

- Improve the activity and durability of Pt alloy by increasing the annealing temperature.

Patent rights available for licensing.

Patent Information:

| App Type |

Country |

Serial No. |

Patent No. |

Patent Status |

File Date |

Issued Date |

Expire Date |

|