Resist Enhancements for Sensitivity and Resolution

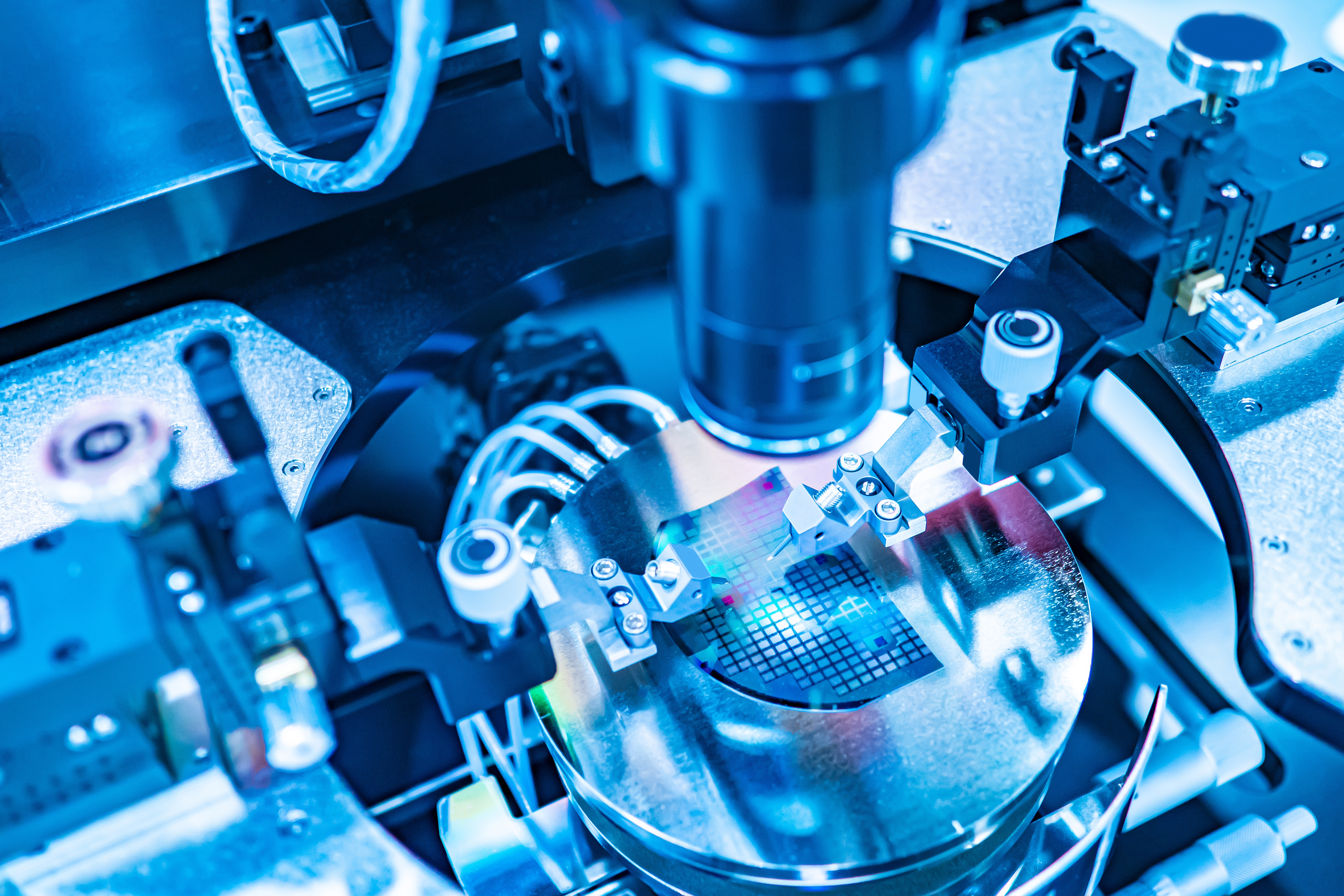

Photoresist layer manufacturing for use in a semiconductor component using a generated electric field.

Due to the unique properties of semiconductors, their use in modern computing/electronic technologies has found wide use in IC, diodes, LED, rectifiers, MOSFET, transistors, solar cells, and other computing materials. Semiconductor fabrication uses a multiple-step sequence of photolithographic/optical lithography and chemical processing, during which electronic circuits are created on a wafer made of a semiconductor material. As part of this procedure, a light-sensitive photoresist layer is coated onto the surface of the wafer to protect the substrate/wafer during subsequent processing steps. As new semiconductor materials are developed for use in more advanced devices capable of faster processing speeds, these designs require improved chemically amplified photoresist materials which can help realize higher photoresist sensitivity, enhanced resolution (e.g., feature dimension transfer to a resist), more precise dimensional/patterning control, and better management of the materials line edge roughness (LER).

Recently, academic interest in manufacturing photoresists with improved vertical profiles, as well as the use of an electric field in chemically amplified photoresist production, has received attention to address current photoresist fabrication issues. Currently, no semiconductor manufacturer embraces these techniques on a commercial basis. The development of these techniques would provide the industry with a preferred photoresist production technique capable of meeting the increased performance demands placed on new semiconductor materials/components.

The developed device/technology uses an electric field generated in the photoresist layer of a semiconductor material after charged particles are embedded into the outer section of the photoresist layer. After electric field generation, a UV light source exposes the photoresist layer to UV energy to chemically alter the composition of the exposed section of the photoresist layer, and then heat is applied, thereby increasing the production of acid in the photoresist layer. The ultimate result is the creation of a local vertical current flow within the resist which can be used to improve product resolution, material efficiency, as well as the material's LER characteristics.

• Can be manufactured using widely available off-the-shelf components

• Eliminates some of the chemical treatment steps required in semiconductor/photoresist photolithographic/optical lithography production

• Realizes improved product resolution, material efficiency, as well as enhancements in semiconductor material LER.

• Semiconductor manufacturing

• Photoresist production

Patent application filed, US20210217583

TRL 1-2

This technology is available for licensing and collaboration opportunities.

Patent Information:

| App Type |

Country |

Serial No. |

Patent No. |

Patent Status |

File Date |

Issued Date |

Expire Date |

|