Method and Pattern of Dispensing Thermal Interface Materials

Pattern of dispensing thermal interface materials that forms thinner layers rapidly with reduced force and avoids post modification of the microprocessor chip and/or cooling device

This invention relates to thermal interfaces between microprocessor chips and cooling devices and to a method of forming thinner TIM layers more rapidly, with reduced squeezing force, and that avoids a requirement for modifying the microprocessor chip and/or cooling device.

The amount and pattern may be predetermined based on the application type, or adaptively determined based on the characteristics of the surfaces or devices to be thermally interfaced. An array of separate fluid regions, individually surrounded by ambient gas, or in some cases, another fluid having lower viscosity, will squeeze faster, with less force, to thinner layers, in comparison to squeezing a continuous fluid layer. These improvements are maximized by keeping the separate high viscosity TIM fluid regions as small as possible throughout the layer formation process. The deposit locations and amounts are chosen such that the separate fluid regions finally merge together shortly before the TIM layer reaches its final state, at a time when the TIM layer thickness is virtually the final layer thickness.

Trapped gasses in the final TIM layer must be minimized since they can degrade thermal and mechanical performance. They can be minimized by squeezing the TIM in reduced ambient pressure, and/or properly designing the deposit locations and amounts such that continuous escape paths exist for gasses until fluid regions finally merge.

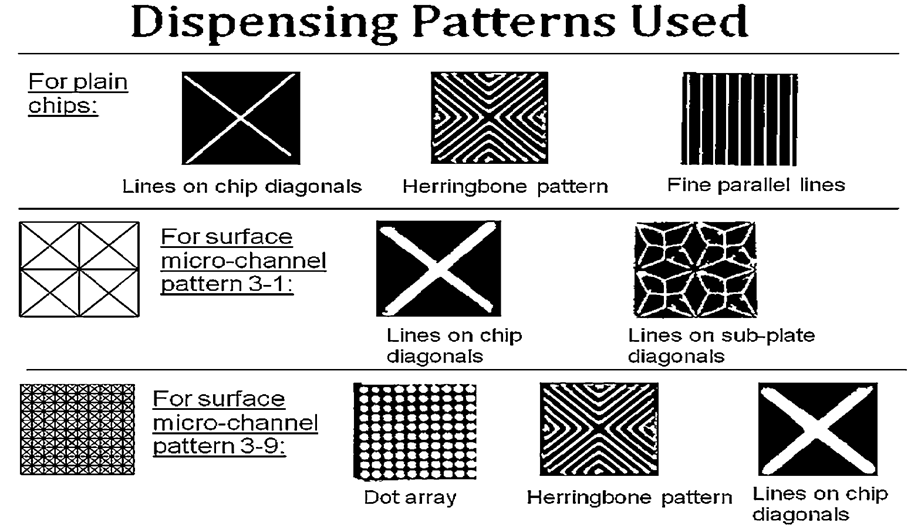

Various dispensing patterns tested

Various dispensing patterns tested

- Faster squeezing of a thermal interface material to thinner layers, with reduced squeezing pressure required

- No requirement for modifying the microprocessor chip and/or cooling device

- Electronics Thermal Management

Patent Information:

| App Type |

Country |

Serial No. |

Patent No. |

Patent Status |

File Date |

Issued Date |

Expire Date |

|